Thread repair inserts are essential components in the world of maintenance and repair. They provide a reliable solution for restoring damaged threads in various materials, including metals and plastics. Understanding their role can be crucial for both professionals and hobbyists who frequently deal with machinery and equipment.

The primary function of thread repair inserts is to restore the functionality of stripped or damaged threads. This can occur due to over-tightening, corrosion, or wear and tear over time. When threads become compromised, the integrity of the entire assembly is at risk, which can lead to failures in machinery or equipment. By using thread repair inserts, you can restore the threads to their original state, ensuring the component remains functional and safe.

One of the significant advantages of using thread repair inserts is their ability to provide a stronger and more durable thread than the original. This is particularly beneficial in high-stress applications where the original threads may have been prone to failure. The inserts are typically made from high-strength materials, such as stainless steel, which can withstand greater forces and resist corrosion.

There are various types of thread repair inserts available, each designed for specific applications. The most common types include helical inserts, solid inserts, and keyed inserts. Each type has its own set of benefits and is suited for different repair scenarios. For instance, helical inserts are ideal for creating strong internal threads in softer materials, while solid inserts are often used in heavy-duty applications where maximum strength is required.

For those seeking quality options, thread repair inserts can be found in a range of sizes and materials to suit various needs. It is important to select the right type and size of insert for your specific application to ensure optimal performance and longevity.

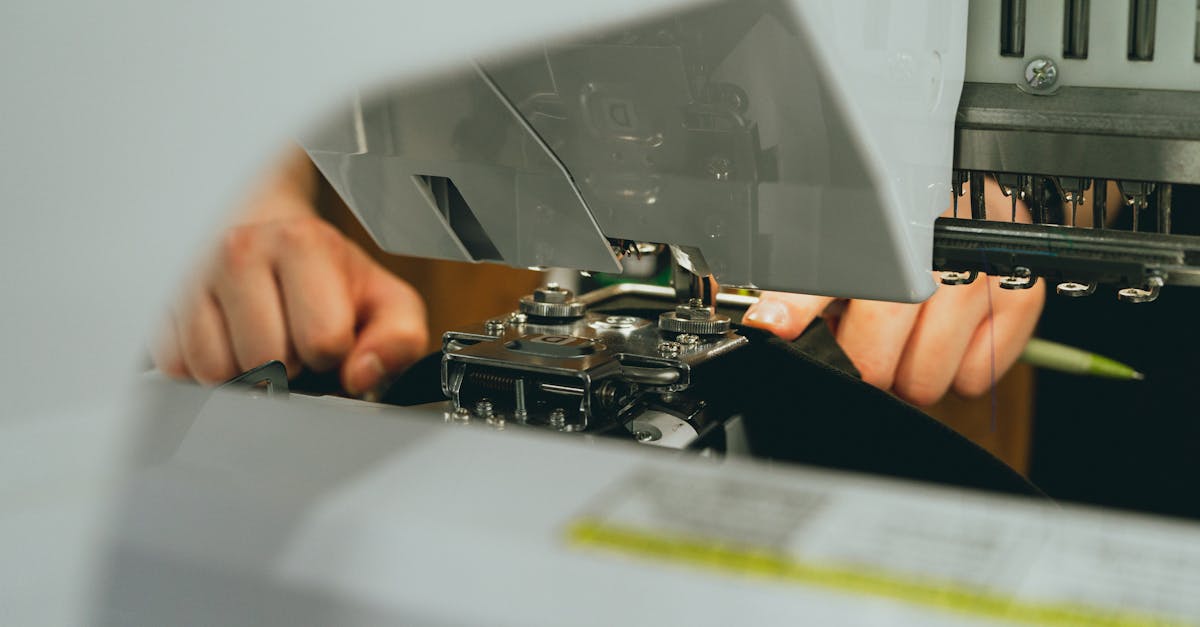

Proper installation of thread repair inserts is crucial to their effectiveness. The process generally involves drilling out the damaged threads, tapping a new thread, and then inserting the repair insert. This creates a new, durable thread that can accommodate the original bolt or fastener. Care must be taken during installation to avoid further damage and ensure a secure fit.

In addition to their practical benefits, thread repair inserts are also a cost-effective solution. Replacing an entire component can be costly and time-consuming. By opting for a thread repair insert, you can extend the life of the component without the need for expensive replacements. This makes them an attractive option for both individual repairs and large-scale maintenance operations.

For more information on selecting and using thread repair inserts, you can visit this resourceful site that provides a comprehensive range of options and insights. Whether you are dealing with automotive repairs, industrial machinery, or simply maintaining home equipment, understanding and utilizing thread repair inserts can save time, reduce costs, and improve the reliability of your projects.

In conclusion, thread repair inserts play a vital role in maintaining the integrity of mechanical components. By restoring damaged threads, they help prevent equipment failures and extend the life of machinery. Their strength, durability, and cost-effectiveness make them an invaluable tool in any maintenance toolkit. Whether you are a professional mechanic or a DIY enthusiast, knowing how to properly use and install these inserts can significantly enhance your repair capabilities.