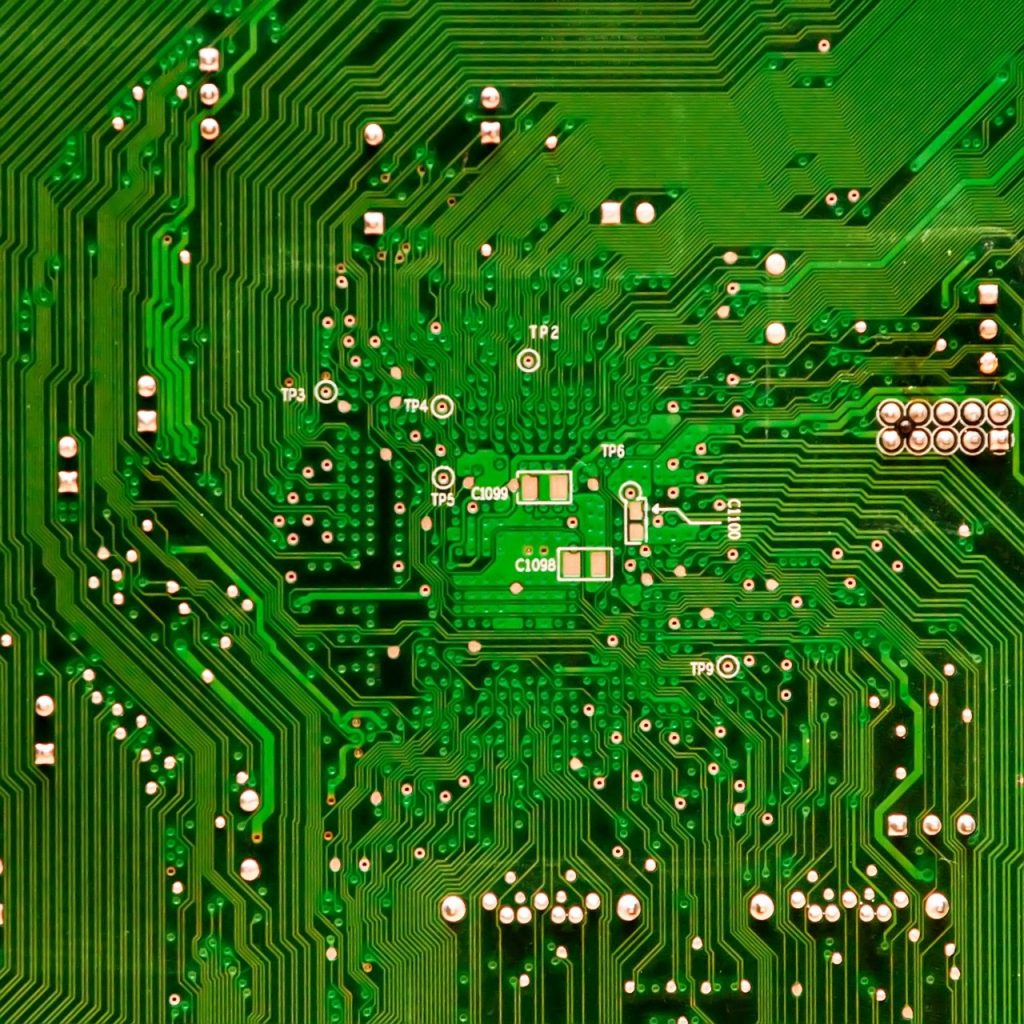

Heavy Copper PCB is a high-frequency electrical circuit board. The copper on this board transfers the heat away from the end product, reducing the overall size. As the current supply increases, it generates more heat but transfers it to an external source. As a result, heavy copper PCB is an effective solution for reducing the end product’s size.

High-frequency applications

High-frequency applications require thick copper PCB, which has several advantages. It can withstand elevated temperatures and conduct excessive current, making it ideal for high-end electronics. It can also withstand repeated thermal cycling, damaging regular circuit boards. This makes it highly popular in the computer industry. In addition to being strong and durable, heavy copper PCB also has great thermal distribution, which makes it perfect for harsh environments.

High-frequency PCB designs require proper layout and design. This is important to avoid unexpected problems. The design process involves the creation of a visual representation of subcircuits and documentation of power and voltage requirements. It also involves incorporating various signals and controlling the impedance.

Automotive

The automotive industry utilizes PCBs in a variety of different applications. These circuit boards are required to be lightweight, miniaturized, and reliable. These boards also offer high levels of thermal and electrical conductivity. These features make them perfect for vehicle speedometers, air conditioning, and music systems. Additionally, they are used in security systems and communications devices.

Because of their high thermal resistance, heavy copper PCB is often used in cars’ power transmission and engine systems. These systems require PCBs that can safely withstand varying temperatures, as temperatures in an engine can fluctuate anywhere from -40C to 165C. Another large application for heavy copper PCB is electric cars, where the charging systems require high currents.

Military

The military and aerospace industries have long utilized heavy copper PCBs to carry heavy components. They are becoming increasingly common in other industrial sectors, and this trend will likely continue. RS Electronics offers complete design and manufacturing services for heavy copper PCBs. To learn more, contact our design and manufacturing specialists.

Military PCBs require special fabrication, assembly, and testing techniques. In addition, they need to be certified to the appropriate MIL-PRF-31032 and IPC 6012 standards. Military PCBs also need special packaging. They should be stored in antistatic bags to avoid static charges and damage to the board.

Aerospace

The aerospace and military industries have long used heavy copper PCBs to carry large power components. Soon, these PCBs will see a wider range of applications in various industries. Its high conductivity makes it an excellent choice for this purpose. As a result, heavy copper is often used in computer motherboards.