Are you tired of manually tracking your inventory and sales? Do you want to increase efficiency and reduce human error in your business? Consider implementing a barcoding system.

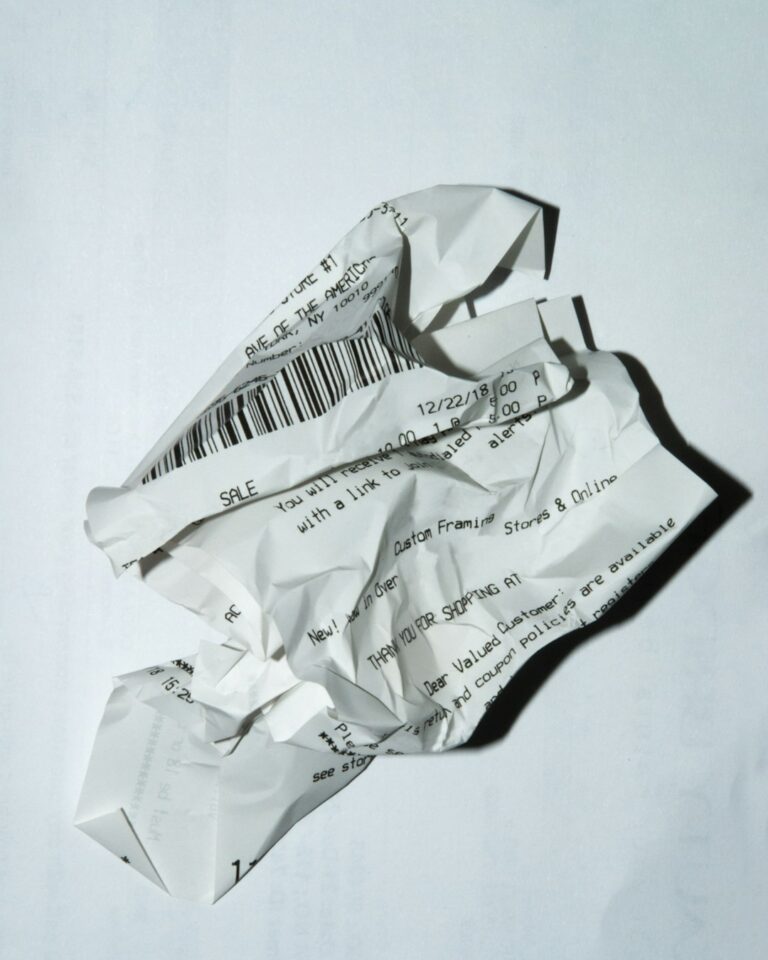

A Barcode Stock System is a method of organizing and tracking inventory and sales using a series of bars and spaces that represent different numbers and letters. The bars and spaces are read by a scanner, which translates the code into information that can be easily stored and analyzed in a computer system.

One of the biggest advantages of using a Barcode Stock System is its accuracy. With traditional manual tracking methods, human error is always a possibility. A misplaced decimal or a miscounted item can lead to huge losses in revenue. With barcoding, the chances of human error are significantly reduced, and you can be confident in the accuracy of your data.

Another benefit is the increased speed of operations. Scanning barcodes takes only a fraction of the time it would take to manually write down information or count items. This allows your employees to focus on other, more important tasks, like customer service or managing inventory levels.

A Barcode Stock System also provides real-time information about inventory levels and sales. This means that you can quickly see what products are selling well and what items are not moving as quickly. This allows you to adjust your inventory levels and product offerings accordingly, to minimize waste and maximize profits.

In addition to these benefits, implementing a Barcode Stock System is relatively easy and affordable. There are many companies that offer barcoding software and equipment, and with a little bit of training, your employees can learn how to use it in no time.

To get started, you will need to purchase a barcode scanner, which is a handheld device that reads the barcode labels on your products. You will also need to purchase barcode labels, which are adhesive labels that can be easily attached to your products.

Once you have the necessary equipment, you will need to input your product information into the barcoding software. This includes item names, descriptions, prices, and any other relevant information. You will also need to assign each item a unique barcode number.

After your products are set up in the system, you can start tracking your inventory and sales. Simply scan the barcode label on each item as it is sold or received in your inventory, and the system will automatically update your data.

To make the most of your Barcode Stock System, it’s important to regularly review and analyze the data it generates. Look for trends in sales and inventory levels, and adjust your operations accordingly. This will help you make informed decisions about purchasing, pricing, and other important aspects of your business.

A Barcode Stock System can bring many benefits to your business, including increased accuracy, efficiency, and real-time data. With a little bit of investment and training, you can implement a barcoding system that will save you time, reduce errors, and improve your bottom line.